Design of 3D knitted structures for impact absorption in sportswear

DOI:

https://doi.org/10.18502/keg.v2i2.605Abstract

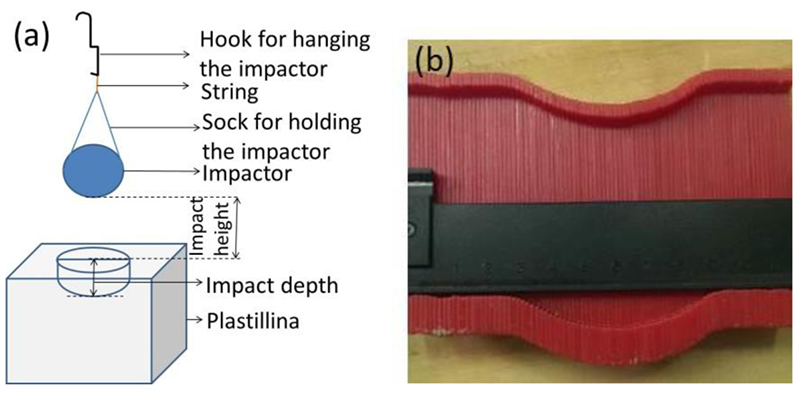

Some sports involve frequent collisions between the players, and between a player and the playing surface, leading to injuries such as muscular strains, dislocations, sprains, lacerations, fractures and soft tissue injuries. In several instances, these injuries are so severe that they may cause bone fracture or dislocation of joints. In recent years, researchers are focusing on reducing these injuries by using protective gears and protective clothing to cover the torso, head, hands and legs. For rugby uniforms, shoulder pads are integrated to reduce the incidence of shoulder injury during the making or receiving of front-on tackles. Although some shoulder pads such as closed cell foams are commercially available, they are often discarded by the players due to their stiffness and discomfort. Hence, in this research an attempt was made to explore the potential of using flexible textile structures to replace the currently used commercial foam. Three flexible textile structures (A, B and C) were designed in three dimensional (3D) structure using Shima Seiki flatbed machine. Each fabric consisted of 3 layers, 2 external (face and back) and one internal layer. Fabric A consisted of mercerized cotton (space dyed) and Elastane external layers, whereas ballistic nylon internal layer. Fabrics B and C were prepared using Dyneema (untwisted) and Elastane external layers and Dyneema (untwisted) internal layer, but with different structures. These textile structures were analysed for their collision protection using the technique of ‘drop test’. The test was based on principle of energy absorption by the textile structure due to the impact of a hard surface with them. It was assumed that the higher is the energy absorbed by the textile structure, the smaller will be the impact to the wearer. It was found that the 3D structures can provide equivalent amount of impact protection as the commercial foam (Sample D). The flexible structures recover easily with the body movement, and provide a high level of comfort. The methods of drop-test including the results are discussed in this paper. The findings of this study suggested that an equivalent level of protection can be achieved with the use of 3D textile structures and higher amount of comfort for the rugby players. Hence, the 3D textile structures can be used as an alternative material to replace the commercial closed foam currently in use in the shoulder pad to achieve similar protection and improved thermal comfort.

References

T. J. Gabbett, Incidence, site and nature of injuries in amateur rugby league over three consecutive seasons, British Journal of Sports Medicine, 34, 98–103, (2000), 10.1136/bjsm.34.2.98.

C. L. Knouse, T. E. Gould, S. V. Caswell, and R. G. Deivert, Efficacy of rugby headgear in attenuating repetitive linear impact forces, Journal of Athletic Training, 38, 330, (2003).

B. Sun, and B. Gu, Frequency analysis of stress waves in testing 3-D angle-interlock woven composite at high strain rates, Journal of Composite Materials, 41, 2915–2938, (2007), 10.1177/0021998307082181.

P. Tan, L. Tong, and G. P. Steven, Micromechanics models for mechanical and thermomechanical properties of 3D through-the-thickness angle interlock woven composites, Composites Part A: Applied Science and Manufacturing, 30, 637–648, (1999), 10.1016/S1359-835X(98)00176-6.

X. Chen, M. Spola, J. G. Paya, and P. M. Sellabona1, Experimental studies on the structure and mechanical properties of multi-layer and angle-interlock woven structures, Journal of the Textile Institute, 90, 91–99, (1999), 10.1080/00405009908658692.

R. Nayak, S. Kanesalingam, S. Houshyar, A. Vijayan, L. Wang, and R. Padhye, Effect of repeated laundering and Dry-cleaning on the thermo-physiological comfort properties of aramid fabrics, Fibers and Polymers, 17, 954–962, (2016), 10.1007/s12221-016-5863-7.

R. Padhye, S. Houshyar, and R. Nayak, Moisture management and thermo-physiological properties of the multi-layered clothing system containing super absorbent materials, in ATC-13, Deakin University, 859–863, (2015).

R. T. Ogulata, Air permeability of woven fabrics, Journal of Textile and Apparel, Technology and Management, 5, 1–10, (2006).