Thermal Stress Flow Analysis in Fabrication of Acetabular Shells Using SLM

DOI:

https://doi.org/10.18502/keg.v2i2.629Abstract

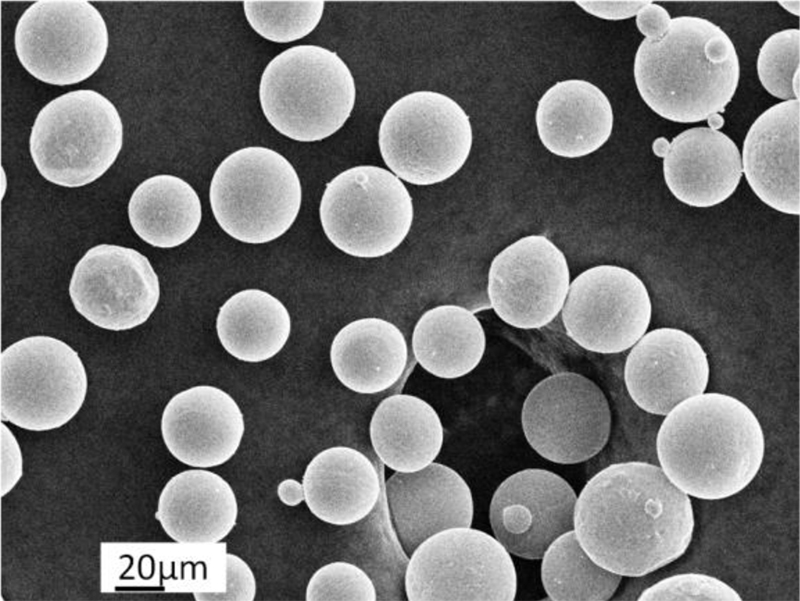

Additive Manufacturing (AM), more popularly known as 3D Printing, is a process for producing functional artifacts by adding layers of materials from data generated directly from 3D solid CAD models. Additive Manufacturing (AM) is the formalized term for what used to be called Rapid Prototyping and what is commonly referred to as 3D Printing. The key to how AM works is that parts are made by adding layers of material; each layer corresponding to a thin cross-section of the part derived from the original CAD data. Although most AM machines produce parts using polymers, there are an increasing number of machines that can directly fabricate in metals. The majority of these machines fabricate from raw material in powder form using a directed energy beam to create a local melt zone. Total hip replacement is recommended for people who have medical issues related to excessive wear of the acetabular, osteoarthritis, accident or age. Researches have shown that large numbers of hip arthroplasties (where the articular surface of a musculoskeletal joint is replaced), hip remodelling, or realignment are carried out annually and will increase in the next few decades. Manufacturing of acetabular shells by using AM is a promising and emerging method that has a great potential to improve public health. Lost wax casting or investment casting is currently used to produce acetabular shells followed by lengthy and complex secondary processes such as machining and polishing. Living organs and medical models have intricate 3D shapes that are challenging to identity in X-ray CT images. These images are used for preparing treatment plans to improve the quality of the surgeries regarding waiting and surgery time per procedure and care regime. For instance, a limited number of hip replacement procedures can be carried out on each acetabulum due to a decrease of bone thickness. Rapid prototyping is a suitable treatment planning tool in complex cases to enhance the quality of surgical procedure and provide long-term stability that can be used to customize the shape and size of the acetabular shell. In this paper, to analyse the manufacturing of a prosthetic acetabular shell, built-up lines resulting from a thermal stress flow and process stopping during the selective laser melting (SLM) AM process, with regarding Gibbs free energy, interfacial energy, and equilibrium temperature will be discussed. Geometrical measurements showed 1.59% and 0.27% differences between the designed and manufactured prototype for inside and outside diameter respectively. Experimental results showed that thermal stress flow in outer surfaces are compressive, but for inner surfaces are tensile, so built-up lines in inner and outer surfaces appear as a groove and dent respectively. The results also indicate that SLM is an accurate and promising method for fabrication of acetabular cup.

References

B Vrancken, L Thijs, J-P Kruth, and J. Van Humbeeck, Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties, Journal of Alloys and Compounds, 541, 177–185, (2012), 10.1016/j.jallcom.2012.07.022.

M Thöne, S Leuders, A Riemer, T Tröster, and H Richard, editors. Influence of heat-treatment on Selective Laser Melting products–eg Ti6Al4V. Twenty-Third Annual International Solid Freeform Fabrication (SFF) Symposium, (2012).

A M Khorasani, M Goldberg, E H Doeven, and G Littlefair, Titanium in Biomedical Applications—Properties and Fabrication: A Review, Journal of Biomaterials and Tissue Engineering, 5, no. 8, 593–619, (2015), 10.1166/jbt.2015.1361.

I. Gibson, Rapid prototyping: from product development to medicine and beyond, Virtual and Physical Prototyping, 1, no. 1, 31–42, (2006), 10.1080/17452750500271298.

I Gibson, D W Rosen, and B Stucker, Additive manufacturing technologies, Springer, (2014).

S M Kurtz, R A Gsell, and J Martell, Crosslinked and Thermally Treated Ultra-High Molecular Weight Polyethylene for Joint Replacements: ASTM International, (2004).

B Sanghera, S Naique, Y Papaharilaou, and A Amis, Preliminary study of rapid prototype medical models, Rapid Prototyping Journal, 7, no. 5, 275–84, (2001), 10.1108/13552540110410486.

A M Khorasani, I Gibson, M Goldberg, and G Littlefair, Production of Ti-6Al-4V Acetabular Shell Using Selective Laser Melting: Possible Limitations in Fabrication, Rapid Prototyping Journal, (2016).

E Chlebus, B Kuźnicka, T Kurzynowski, and B Dybała, Microstructure and mechanical behaviour of Ti–6Al–7Nb alloy produced by selective laser melting, Materials Characterization, 62, no. 5, 488–95, (2011), 10.1016/j.matchar.2011.03.006.

C Heisel, J A Kleinhans, M Menge, and J P Kretzer, Ten different hip resurfacing systems: biomechanical analysis of design and material properties, International orthopaedics, 33, no. 4, 939–43, (2009), 10.1007/s00264-008-0607-y.

O Rosenberg, V Vozny, C Sokhan, J Gawlik, A Mamalis, and D-J Kim, Trends and developments in the manufacturing of hip joints: an overview, The International Journal of Advanced Manufacturing Technology, 27, no. 5–6, 537–42, (2006), 10.1007/s00170-004-2189-1.

J P Kretzer, J A Kleinhans, E Jakubowitz, M Thomsen, and C Heisel, A meta-analysis of design-and manufacturing-related parameters influencing the wear behavior of metal-on-metal hip joint replacements, Journal of Orthopaedic Research, 27, no. 11, 1473–80, (2009), 10.1002/jor.20921.

A M Khorasani, I Gibson, Chegini N Godarzvand, M Goldberg, A H Ghasemi, and G Littlefair, An improved static model for tool deflection in machining of Ti–6Al–4V acetabular shell produced by selective laser melting, Measurement, 92, 534–44, (2016), 10.1016/j.measurement.2016.06.031.

A M Khorasani, I Gibson, M Goldberg, and G Littlefair, A survey on mechanisms and critical parameters on solidification of selective laser melting during fabrication of Ti-6Al-4V prosthetic acetabular cup, Materials & Design, 103, 348–55, (2016), 10.1016/j.matdes.2016.04.074.

A M Khorasani, I Gibson, M Goldberg, J Nomani, and G Littlefair, Machinability of Metallic and Ceramic Biomaterials: A review, Science of Advanced Materials, 8, 1491–511, (2016), 10.1166/sam.2016.2783.

O L Harrysson, O Cansizoglu, D J Marcellin-Little, D R Cormier, and H A West II, Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology, Materials Science and Engineering: C., 28, no. 3, 366–73, (2008), 10.1016/j.msec.2007.04.022.

L Murr, S Quinones, S Gaytan, M Lopez, A Rodela, E Martinez, et al., Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications, Journal of the Mechanical Behavior of Biomedical Materials, 2, no. 1, 20–32, (2009), 10.1016/j.jmbbm.2008.05.004.

L Zhang, D Klemm, J Eckert, Y Hao, and T Sercombe, Manufacture by selective laser melting and mechanical behavior of a biomedical Ti–24Nb–4Zr–8Sn alloy, Scripta Materialia, 65, no. 1, 21–4, (2011), 10.1016/j.scriptamat.2011.03.024.

L. C. Hieu, N. Zlatov Jvs, E. Bohez, L. Khanh, P. H. Binh, P. Oris, and Y. Toshev, Medical rapid prototyping applications and methods, Assembly Automation, 25, no. 4, 284–92, (2005), 10.1108/01445150510626415.

E C Santos, M Shiomi, K Osakada, and T Laoui, Rapid manufacturing of metal components by laser forming, International Journal of Machine Tools and Manufacture, 46, no. 12, 1459–68, (2006), 10.1016/j.ijmachtools.2005.09.005.

A M Khorasani, M R Soleymani Yazdi, and M S Safizadeh, Tool Life Prediction in Face Milling Machiningof 7075 Al by Using Artificial Neural Networks (ANN) and Taguchi Design of Experiment (DOE), International Journal of Engineering and Technology, 3, no. 1, 30, (2011), 10.7763/IJET.2011.V3.196.

M E Glicksman, Principles of solidification: an introduction to modern casting and crystal growth concepts, Springer, (2010).