Design and fabrication considerations for three dimensional scaffold structures

DOI:

https://doi.org/10.18502/keg.v2i2.604Abstract

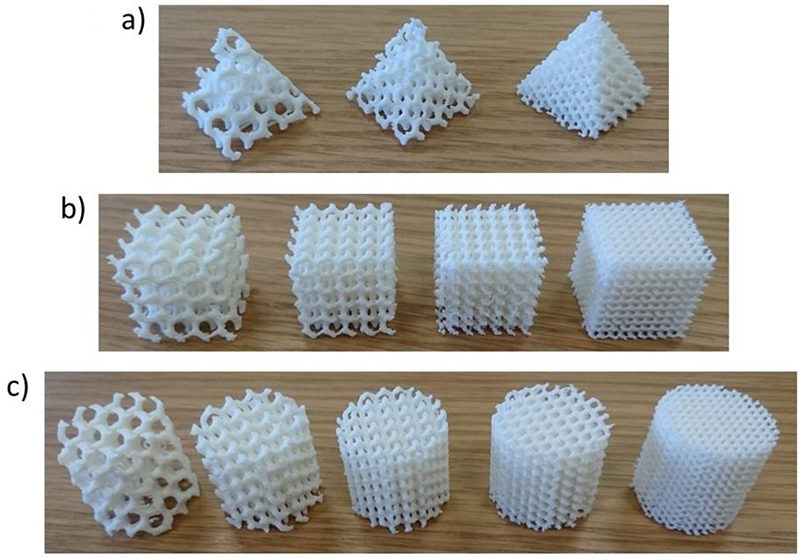

Porous three dimensional structures have seen extensive investigation among design engineers for a wide range of novel applications. The fabrication of such designs would not be possible using traditional manufacturing approaches owing to the dimensional intricacy of such structures, but have now become a distinct possibility owing to the maturity of 3D printing technologies. In this study, we have examined the creation of novel unit cells from mathematic surface renderings as a basis for creating tailored porous structures, before realising the final designs through Fuse Deposition Modelling (FDM) 3D printing. We examined the use of Gyroid and Schwarz primitive (P) surfaces to create novel unit cells not typically found in design software libraries. We then transpose these structures into several test geometries comprising a cylinder, cuboid and tetrahedron, which will adequately test limits of design and fabrication in regular and irregularly shaped structures. It was found that the porosities of the resulting models could be adjusted through discrete dimensional changes in the unit cell and digital wrapping procedures. It was also found that models could be fabricated using FDM printing to a minimum pore diameter of approximately 1mm with a high degree of accuracy and repeatability. Ultimately this work will provide guidance to engineering's when creating porous structures and could find usefulness in applications where optimal material usage versus porosity are required, such as in high throughput 3D fluidic applications, such as heat exchangers and tissue engineered structures.

References

D. W. Hutmacher, Scaffolds in tissue engineering bone and cartilage, Biomaterials, 21, 2529–2543, (2000), 10.1016/S0142-9612(00)00121-6.

Shapeways, 2016.

I. Gibson, D. W. Rosen, and B. Stucker, Additive manufacturing technologies, vol. 238, Springer, (2010).

S. J. Hollister, Porous scaffold design for tissue engineering, Nat Mater, 4, 518–524, (07//print 2005), 10.1038/nmat1421.

A. Fukuda, M. Takemoto, T. Saito, S. Fujibayashi, M. Neo, D. K. Pattanayak, et al., Osteoinduction of porous Ti implants with a channel structure fabricated by selective laser melting, Acta Biomaterialia, 7, 2327–2336, (5//2011), 10.1016/j.actbio.2011.01.037.

F. P. W. Melchels, K. Bertoldi, R. Gabbrielli, A. H. Velders, J. Feijen, and D. W. Grijpma, Mathematically defined tissue engineering scaffold architectures prepared by stereolithography, Biomaterials, 31, 6909–6916, (9//2010), 10.1016/j.biomaterials.2010.05.068.

K. Michielsen, and D. G. Stavenga, Gyroid cuticular structures in butterfly wing scales: biological photonic crystals, Journal of The Royal Society Interface, 5, 85–94, (2008), 10.1098/rsif.2007.1065.

X. Cao, D. Xu, Y. Yao, L. Han, O. Terasaki, and S. Che, Interconversion of Triply Periodic Constant Mean Curvature Surface Structures: From Double Diamond to Single Gyroid, Chemistry of Materials, 28, 3691–3702, (2016), 10.1021/acs.chemmater.6b00308, 2016/06/14.

J. Shin, S. Kim, D. Jeong, H. G. Lee, D. Lee, J. Y. Lim, et al., Finite Element Analysis of Schwarz P Surface Pore Geometries for Tissue-Engineered Scaffolds, Mathematical Problems in Engineering, 2012, 13, (2012), 10.1155/2012/694194.