Preparations and Characterizations of Hierarchical Macropore Activated Carbon Monolith Electrode from Rubber Wood for Supercapacitor Application

DOI:

https://doi.org/10.18502/keg.v1i1.499Abstract

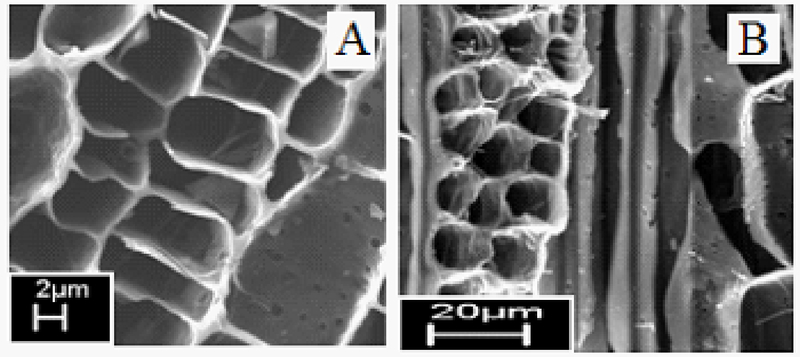

Preparation of hierarchical macropore activated carbon monolith (HMACM) from rubber wood was investigated. The samples were prepared with small cutting of rubber wood in cross sectional method. The electrode preparation was started by pre-carbonization process followed by carbonization at 600 oC and physical activation process at 900 oC in N2 and CO2 gas atmosphere, respectively. The samples then were followed by chemical activation process with combination of chemical activation agent of KOH and HNO3 solutions. The HMACMs were neutralized by immersing the samples in copious amount of water and dried the samples for 24 hours. Porosity properties were performed by N2 adsorption-desorption data and morphology characterization was analyzed by scanning electron microscope (SEM) instrument. The electrochemical properties was studied by electrochemical impedance spectroscopy, cyclic voltammetry and charge-discharge at constan current methode. The SEM micrograph and adsorption-desorption data were also proved that the HMACM sample have a hierarchical macropore at the surface and crossectional section. The porosity data shown the HMACM sample have BET surface area of 331 m2/g with average pore diameter of 1.7 nm. Equivalent series resistance and optimum capacitance specific of the HMACM electrode of 0.77 Ohm and 154 F/g, respectively. In conclusion, this study showed that the preparation method would propose as a simple method of HMACM electrode preparation technique for supercapacitor applications.

References

A. Burke, R. Kotz, and M. Carlen, J Power Sources, (2000).

A. Burke, R&D considerations for the performance and application of electrochemical capacitors, Electrochim Acta, 53, 1083–1091, (2007).

E. Frackowiak and F. Béguin, Carbon materials for the electrochemical storage of energy in capacitors, Carbon, 39, 937–950, (2001).

E. Taer, M. Dareman, I. A. Talib, A. Awitdrus, S. A. Hashmi, and A. A. Umar, Int J Electrochem Sci, 6, no. 8, 3301–3315, (2011).

E. Taer, M. Deraman, I. A. Talib, A. A. Umar, M. Oyama, and R. M. Yunus, Physical, electrochemical and supercapacitive properties of activated carbon pellets from pre-carbonized rubber wood sawdust by CO2 activation, Curr Appl Phys, 10, 1071– 1075, (2010).

X. ia. He, P. Ling, J. Qiu, et al., Journal of power sources, 109–113, (2013).

R. Farma, M. Dareman, A. Awitdrus, et al., in Bioresuorce Technology, 254–261, 2013.

M. C. Liu, B. Kong, P. Zhang, Y. C. Luo, and L. Kong, Porous wood carbon monolith for high-performance supercapacitors, Electrochim Acta, 60, 443–448, (2011).

J. Chang, G. Zhiyong, W. Xiaorui, and D. Wu, Electrochimica Acta, 290–298, (2015).

J. Chimiola, G. Yushin, R. Dash, and Y. Gogotsi, J Power Sources, 158, 765–772, (2006).

K. S. W. Sing, D. H. Everret, R. A. W. Haul, L. Moscou, R. A. Pierotti, J. Rouquerol, and T. Siemieniewska, Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984), Pure Appl Chem, 57, 603–619, (1985).