Manufacturing Execution Systems And A Sectoral Application

DOI:

https://doi.org/10.18502/kss.v1i2.648Abstract

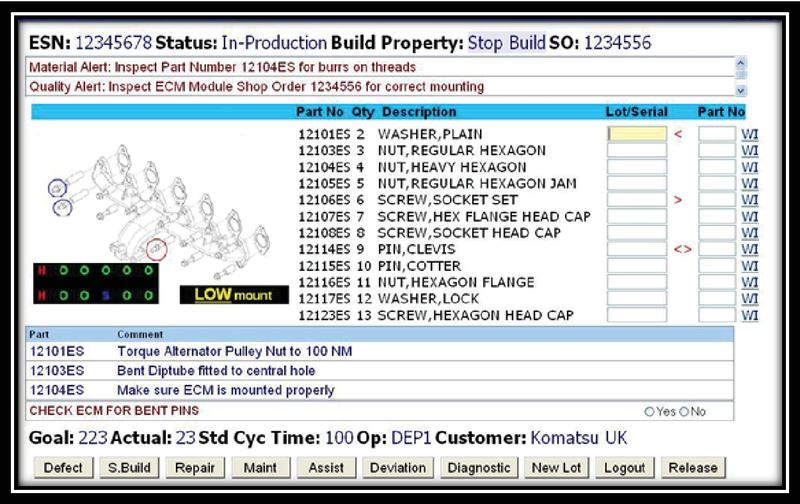

Information systems have widespread usage on Manufacturing Systems. Most companies need tracking production processes with information systems to become prominent in highly competitive environment. There are some specific metrics need to be followed and important to access these datas on time and also should be reliable. These metrics include all manufacturing and quality processes. In this context; efficiency, line stoppages, malfunction and interruptions, body and supplied part trace ability informations are needed. This study MES (Manufacturing Execution Systems) is the system developed for tracking production processes. MES is working from receipt of order to delivery of the product that are the essentials for the production activities to achieve real time status of all manufacturing data. In this way, all information which not manually recorded or takes long process time to record or can be tracked instantaneously and these records can be reached and analyzed in the future. The system also provides accurate data for us. In this study all phases from design to implementation of an automotive subindustry firm’s MES application designed based on integrated software process requirements are depicted. Relevant system’s integrated software will be implemented to Module Line. This study will allow tracking related product’s all process, decision making and traceability data with serial numbers.

Keywords: MES, Manufacturing Execution Systems, Information Systems, Traceability

Note: Yılmaz Gökşen was mistakenly omitted from the author list when this article was first published on (19 March, 2017). Yılmaz Gökşen was added to the author list on (18 May, 2017). We apologise for the error.

References

Cube Technology Inc, The Open Control System, Milford, MA, 2001.

T. H. Davenport and L. Prusak, (2001), Is Dünyasinda Bilgi Yönetimi: Kuruluslar Ellerindeki Bilgiyi Nasil Yönetirler. Çev. Günhan Günay.

Demir. Hulusi, (2009)., Sevkinaz Gümüsoglu. Üretim Yönetimi (Islemler Yönetimi, .

Gerald. RIVEST, Verimliligin Ölçülmesi ve Yönetim Araci Olarak Kullanilmasi , baslikli teblig, Isletmelerde Verimliligin Gelistirilmesi Konusundaki TISKILO Isbirligi Projesi Çerçevesinde 1. Verimlilik Egitimi Semineri, p. 82, (1991).

J. Hunt and G. M. Mair, Manufacturing Engineers Reference Book, Chapter, 4, (1993).

B. Kobu and Üretim. Yönetimi, Baski, Beta Basim Yay. Dag. Sti. Istanbul, (2005).

S. R. Lawrence and E. C. Sewell, Heuristic, optimal, static, and dynamic schedules when processing times are uncertain, Journal of Operations Management, 15, no. 1, 71–82, (1997).

Michael. McClellan, Applying Manufacturing Execution Systems, St. Lucie Press, Boca Raton, Fl, 1997.

MES. ConferenceExposition, Introduction to Manufacturing Execution Systems, Maryland, Baltimore, 2001.

ST. Otomasyon Dergisi, MES (Manufacturing Execution Systems) Üretim yönetiminden beklenenler Ekim, http://www.haberortak.com/Haber/Otomasyon/ /MES-Manufacturing-Execution-Systems-Uretimyonetiminden-beklenenler. php.

U. Yozgat, I. Edin, and İ. Edin, Uluslararasi Isletmelerde Enformasyon Teknolojileri ve Kurumsal Entegrasyon Politikalari Ekonomi ve Yönetimi Kongresi, Eskisehir, (2004).